In early 2014 I bought a Makerbot Mini and have also had use of an Ultimaker 2. Both are FFM machines with different features and quirks. I have become a big fan of Ultimaker and most of the larger or more detailed models I post will have been made on the Ultimaker.

This is the largest project to date which began when I went on hiatus from working on the television show, Defiance. I had originally planned on using the Makerbot to output the part, but as soon as the Ultimaker 2 became available in the US it became the target platform.

Since the Makerbot Mini I have only prints as high as 200 microns I started there instead of maxxing out the resolution from the Ultimaker. I did this for several reasons, but the most important one was speed after I saw the build times for higher resolutions. It would also serve as a fair comparison between build quality and speed if the parameters were as close as possible. The Mini is not in the same class in any was as the Ultimaker 2 so it would never be fair to compare the 2, but it made sense at the time.

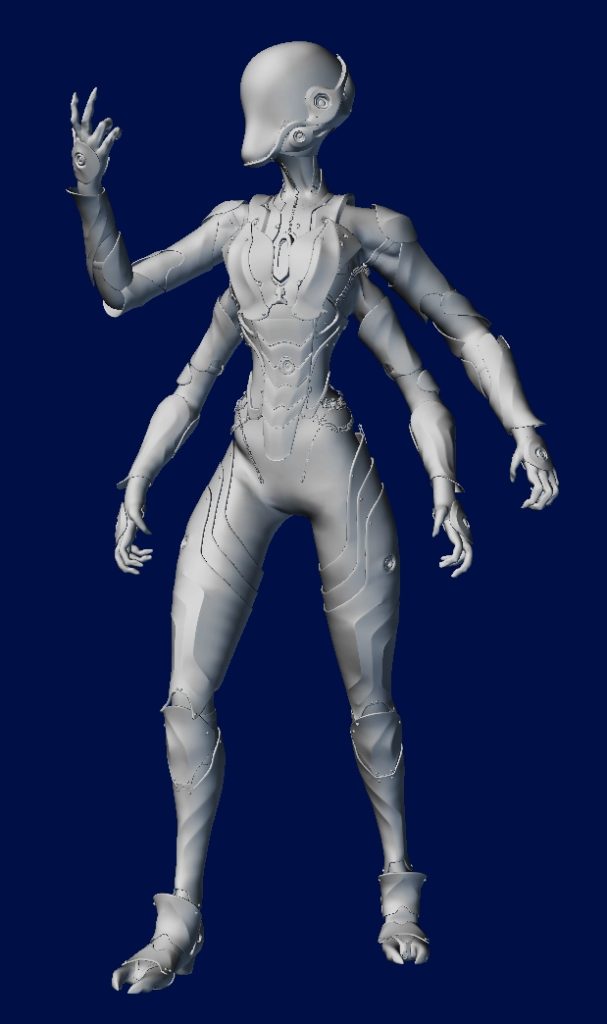

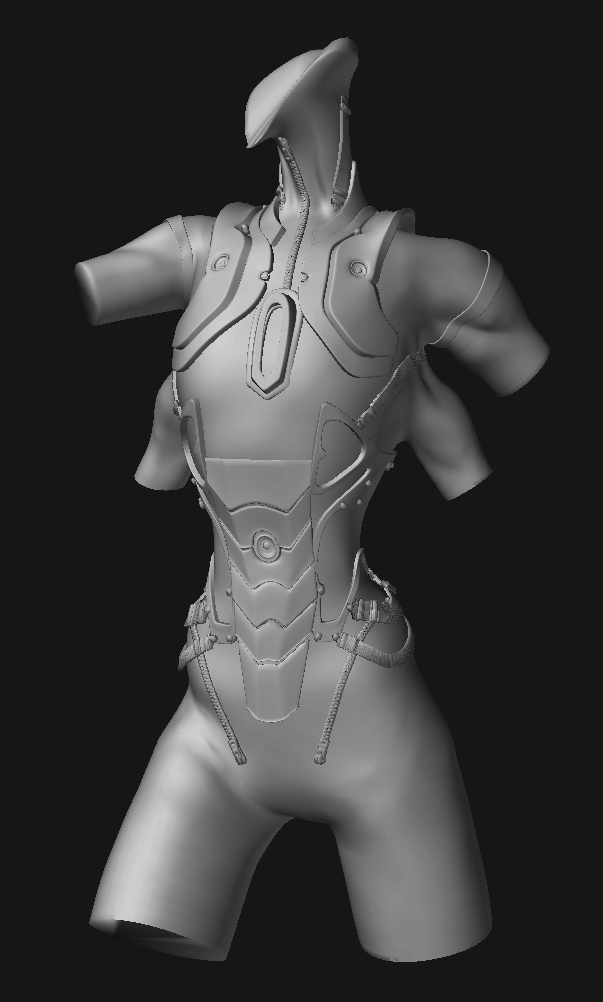

The two largest pieces by volume were the two pieces of the torso so along with the head I started there and gradually made parts for the whole body.

The build quality of the Ultimaker really surprised me but the speed is where this machine really makes its reputation – silent and fast. A great combination for folks who want to use it in a home workshop.

The limbs of the model have numerous pieces of armor which curl around and have very tight and small undercuts – it was a real torture test for the builds.

When it was all finished I gave it a coat of primer and headed off to the Long Beach Comic Con where I had it on display – with other prints from the Makerbot being dwarfed by the 2 foot tall final model.

I intend to give the model the full paint job as close as possible to the paint scheme in the original CGI. One of the bigger projects in the future is to use some translucent filaments to more accurately depict the clear parts of the armor on the helmet and on the waste.